Designing for 3D Printing - Overhangs

Overhangs and bridges are common features in 3D models that can challenge the printing process, often leading to drooping, stringing, or failure if not managed correctly.

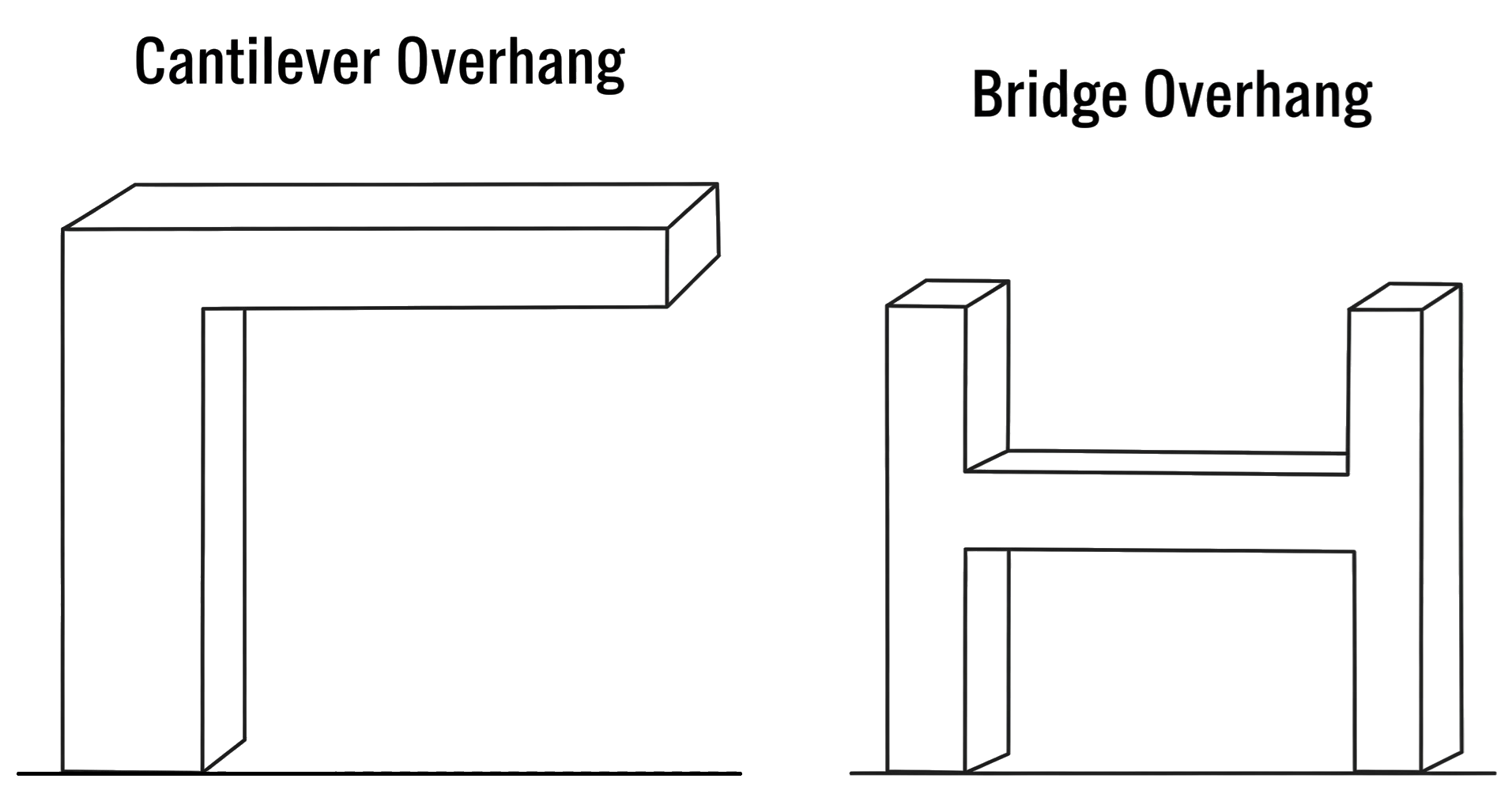

There are two typical overhang types; Cantilever and Bridge.

The best way to solve a problem is to eliminate it during design. By making strategic changes to your design, you can often remove the need for supports or ensure success with minimal adjustment.

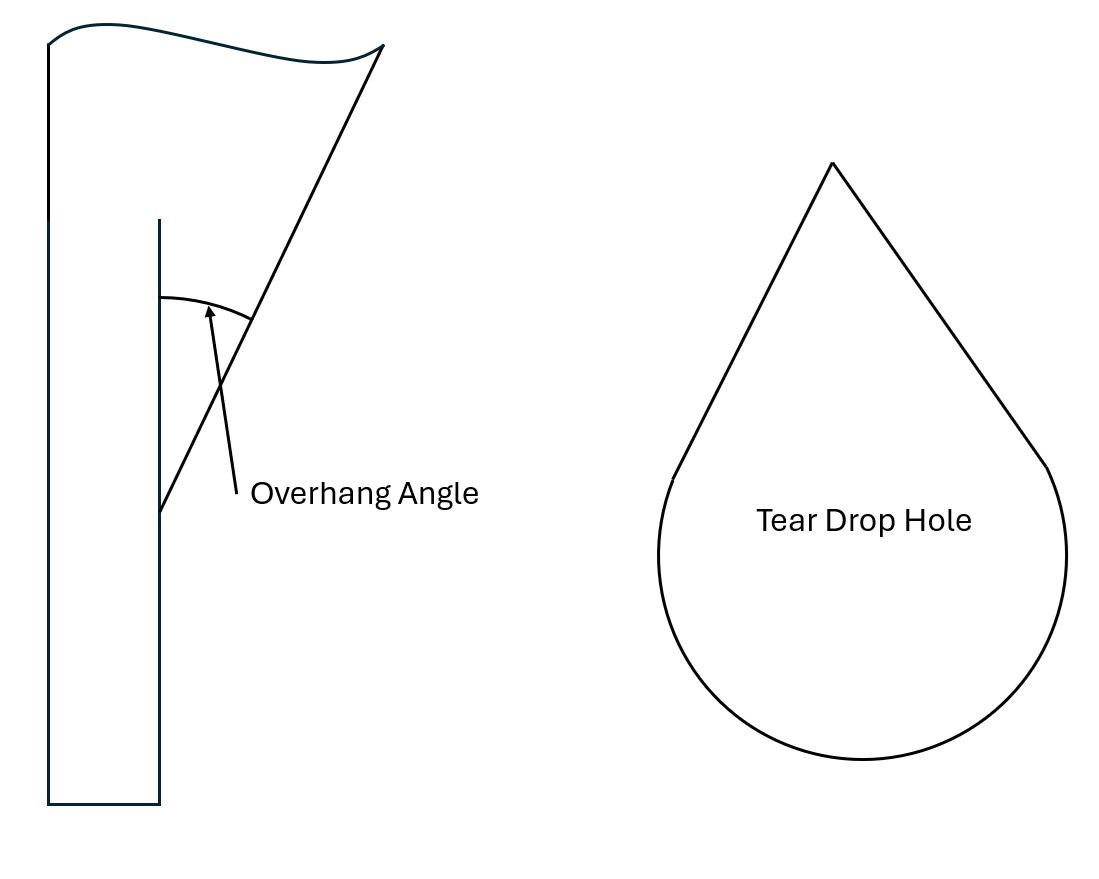

Overhang Angle

Overhang Angle is used to measure how severe the overhang is. Most Fused Deposition Modeling (FDM) 3D printers can successfully print an overhang up to a 45-degree angle from the vertical without needing support. However often times we limit overhang angles to 30 degrees for high volume production. This allows for better part quality at higher print speeds.

Design Strategies

Instead of designing a sharp, 90-degree overhang (which requires full support), introduce a chamfer or taper. A 30-45 degree overhang allows each subsequent layer to be partially supported by the layer below it, ensuring a successful print without extra material.

For rounded features like holes, the unsupported bottom curve can droop. Changing the circular profile to a teardrop shape or adding a small internal fillet to the bottom of the curve can reduce the unsupported area, allowing the printer to bridge the feature more effectively.